The last few months have brought so many exciting changes to Verb. Last week Kristine told the story of the California Wool Project, our first adventure with creating our own California merino yarn from sheep to shelf. This has been such an illuminating undertaking, and gives me a new sense of reverence for all the people behind the beautiful yarns we carry.

One of them is Pam Allen, owner and creative director at Quince & Co. Pam Allen has been a pillar of the knitting world since long before Quince's inception. She's the author of Knitting for Dummies, edited Interweave Knits from 2003-2007, and served as the creative director at Classic Elite, before founding Quince and Co. with Carrie Hoge and Bob Rice. She sat down to answer a few of our questions about Quince and the revival of the domestic wool market.

----------------------------------------------------------------------------------------------------------------------------------

People love Quince. They're excited to see it at Verb, and they're excited about the fact that it's domestically produced. What do you want our customers to know about Quince that they don't already?

Without sounding too pessimistic, I’d love for people to know how hard it is to create a consistent yarn product in this country when the textile industry is dying. The processing, spinning, dyeing companies that used to thrive here are rapidly going out of business. So sad. And, for me, sadder than the equipment loss is the vanishing expertise. Spinning, dyeing -- these are as much art as formula. What counts is an intuitive feel for a yarn/color that only comes from a long an intimate relationship with fiber. The head dyer at our dye house is 68 years old. He had his first job in a dye house when he was 17. The man who makes yarn at our primary spinning mill is 65—again, he has a lifetime of spinning experience. When these men retire, who will take their place? I wish that we had apprentice programs for these skills, but without a demand for them, no one is interested in learning the trade.

That said, the companies that remain alive in this country are survivors, and some are flourishing. One of the mills we use almost went under in the 1990’s when their primary customer, L.L. Bean, went overseas for production. The mill teetered until they found a steady customer. They now spin tons of yarn used for the insides of baseballs. Not a glamorous or romantic product, barely a textile, but it’s keeping them in business. And we are SO grateful.

I hope, in the NEAR future that big companies like Eileen Fisher and Ralph Lauren who talk about craft and domestic manufacture make a bigger push to produce things here. The scale of their demand would greatly increase and strengthen the industry. Hope, hope.

Quince seems to fill a niche that hadn't been filled. What did you want from your own yarn that you weren't finding on the market already? Tell us about the process of balancing quality, price, and responsible production.

Mostly I was interested in making a quality yarn in the US that could compete with imports. Living in New England with empty mill buildings all around, vast stretches of them, makes it hard not to want to DO something. When I met someone who was spinning yarn down the street, I couldn’t resist seeing if it was possible to make a commercial, not artisan-expensive, local yarn. And I wanted the yarn to be a completely domestic product—from fiber to mill to dye house. The pressure to use imported materials is great. The prices and quality are sometimes better.

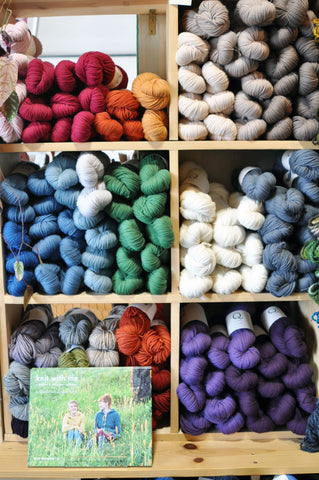

I also love a beautiful basic yarn that shows stitches—and I love a big, strong palette. What could be more fun than imagining the perfect yarn and then trying to make it? We started with four weights, from sport weight to chunky. We could have spun a single ply and increased the weight of the yarn by adding plies to form a heavier yarn. But we decided that it would be more fun and interesting to give each weight yarn a different personality. For example, Puffin is a round single ply, and little Finch is a smooth four-ply.

And we wanted to present the yarn/patterns in a beautiful sophisticated, modern way. These days, there’s so much beautiful photography on the web. The pictures on Pinterest are sometimes breathtaking. We wanted to be in that visual league. Carrie Hoge, art director and in-house photographer, has done a superb job giving us a beautiful face.

Quince yarns use natural fibers exclusively. The yarns are all named after birds, and many of the color names come from animals, vegetables and minerals. Tell us about Quince's relationship with the natural world. Why the commitment to wool and other natural fibers? For knitters who are new to using natural fibers, what's your advice?

I love, love, love that our yarn comes from a living animal. All my life I encountered yarn as a packaged ball on a shelf. Now I see where it starts. Each bale of fiber is different. The climate, mix of breeds, time of shearing all contribute to the qualities of a given bale. A synthetic fiber is the same every time. I think it’s kind of wonderful that each batch of yarn we spin, though very similar to the one before, is also unique because it’s made from a different set of animals. People often ask us which breed of sheep we use. But commercial fiber is mostly sold on the basis of generic characteristics, not by specific animal type. We buy fiber in different grades for our different yarns. The wool is graded by fineness (average micron count), staple length, crimp, and whiteness. You can see the difference sometimes in the whiteness from bale to bale. Our color Frost is a very light gray. If the fiber has more yellow in it than usual, the dyed color is a warmer gray. If the fiber is very white, the Frost lot comes out cooler. We could bleach the yarn for consistency, but that would run counter to our effort to be as planet friendly as we realistically can.

For knitters new to natural fibers, I can only say that I wouldn’t work with anything else. Natural animal fibers have all the wonderful qualities in the skein that they do on the animal—they’re resilient, insulating, moisture absorbing. And they’re renewable. No animals suffer or are killed in the process. And, no small thing for me, ranches and farms preserve the natural environment. I’d rather have more of those on the landscape than factories making synthetic yarns. Call me a romantic. I’ll stop here.

Though I could go on.

Where is Quince milled? Why was it important to use domestic wool and a domestic mill? When you do use imported materials, like the silk in Tern and the linen in Sparrow, how do you select your suppliers?

We source our wool fiber from a large broker in the south. We’ve recently introduced an alpaca/wool blend and sourced the alpaca from the US, not an easy task. If I went to a broker, I could get wonderful alpaca at a great price, but it would come from South America or New Zealand. Finding a good source for consistent quality in good quantities is difficult. That said, growers are getting more organized and we’ve made some good contacts. We hope the next time we look for alpaca, we’ll be buying lovely stuff all graded and sorted. And we’ll never look back.

As for silk. We buy it from a broker and it probably comes from China. We’re looking into other sources. Nothing exists in quantity in the US, but we’re looking into sources with ‘traceability’ in other parts of the world. We use tussah silk (not mulberry), which has a better eco footprint. The silk fiber is taken from the pod AFTER the worm has turned into a moth and flown away.

As for Sparrow, our linen yarn. I have a contact in Italy who sources and spins organic linen. I couldn’t resist. Even though the yarn isn’t from the US, it is at least certified organic, so we know that the farm is using benign practices. And it’s good to have a summer fiber/yarn. And we really like linen. Cotton is a horrendous plant eco-wise—it requires pesticides and way too much water. So no cotton for us until we can source something that we can feel good about.

Does Quince represent a shift in the relationship between yarn manufacturers and designers? Between yarn makers, designers and knitters? It seems like there's recently been a surge in designers starting their own yarn labels. How is this changing the yarn market?

Great question. The knitting industry has changed dramatically in the last ten years. The internet, i.e. blogs, Ravelry, younger knitters, has—how to say it—democratized the market. So many people are designing now. It’s great. No longer are a small handful of publishers deciding who to work with. Designers can make more money self-publishing. So much is up for grabs. This open situation has made possible a more intimate connection between yarn makers and designers and knitters. Yarn companies, including ours, can greatly benefit from collaborations with independent designers. As one example, Hannah Fettig shares an office with us and is now using our yarns in many of her designs. She’s working on a Sparrow collection that we’ll launch this spring. We love that she can bring her design eye and aesthetic to our yarns and do something different with them. And Stephen West has used our yarns exclusively in a book he’s working on right now. Cecily Glowik-MacDonald has done many designs for us. I could go on…

I enjoyed reading about the Ricefield Collective on your blog. Can you tell us about the project? How did Quince get involved? Why is it important to you to be part of a project like this?

Last year, we got an email from Meredith Ramirez asking about our yarns for her project. We sent them to her and next thing we knew, she’d produced a wonderful video describing Ricefield Collective and launched a very successful Kickstarter campaign. Meredith is better at describing the project than I am, but essentially, the idea is to help women (mostly) in a rural part of the Philippines to find sustainable work. They live in a part of the country where for millennia the locals farmed rice on a system of terraces. As often happens, the people of the province are leaving their homes, and this wonderful heritage landscape and culture, to work in cities. Perhaps, through fiber and knitting, they can find a way to supplement their farming and stay home. I feel honored that Meredith wanted to use our yarns for the project. Perhaps Meredith felt an affinity for what we’re trying to do. I know it sounds grandiose, but if we can be part of a demand for American wool and American yarn, we can help to keep a fading industry from dying out entirely. In the Philippines, the Rice Collective is trying to keep a tradition, a people, a landscape alive. If we value something—in our case, sheep on the plains, knowledge and skills, our historic textile industry--we need to think about what it needs, how we can encourage it and make it thrive.

----------------------------------------------------------------------------------------------------------------------------------

-There's been a lot of discussion about hand-knitting's contemporary renaissance. As more people have started knitting in the last ten years, farmers, woolen mills, designers and entrepreneurs have stepped up to meet the larger and more diverse demand for higher quality yarn and supplies, and more sophisticated patterns. The changes have been overwhelmingly positive, and there's a lot to be optimistic about in yarn's future. But renaissances don't appear out of thin air. Countless dedicated and visionary people have sweat blood to put beautiful and responsibly-produced yarn on the market, and to revive the USA's ailing textile mills. For me, this interview is a great reminder of how much love, energy and hard work has gone into the modern yarn industry already, and how much potential the future holds. Thanks, Pam. -HD