Our visit to Thirteen Mile Farm was certainly a highlight of our trip. I first read about Thirteen Mile in the book Shear Spirit. The owner, Becky Weed, raises her own sheep and has built a mill where she makes yarn from her wool. There are two outstanding reasons I am particularly fascinated with her work: she is a natural dyer and she uses solar power to run her mill. Before working at Verb, Adrienne worked for a solar electrical company, and she still has a lot of interest in solar power. Add in our love of fiber and natural dyes, and this was pretty much a dream to see in person.

Becky raises two types of sheep: Romney and South African Merino.

She makes mainly three types of yarn from their wool: a sport weight, a worsted weight, and an irregularly spun bulky.

She creates yarn that has been naturally-dyed and is naturally colored. She also makes large wool batts and has a felting machine which enables her to make large pieces of wool felt.

Becky was kind enough to take a break and show us the mill.

The mill pretty much runs 100% on solar power due to the two solar panels found on the top and to the left of the mill.

This is the washing station for the wool. All the water used in the washing cycle is saved as grey water and used to water the fields.

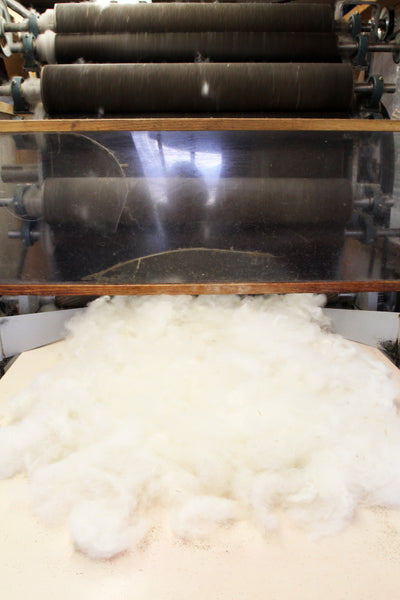

Once the wool has been washed it goes through a carding machine.

If Becky is going to make a yarn that is naturally dyed, rather than a naturally colored yarn, she takes the washed fleece and dyes it. She then combines colors in the carding process resulting in yarn that has a heathered look.

And then is stripped into roving.

Becky takes extra time in this part of the process. While it is possible for her to move to the next step in the process, the spinning, she puts the roving through a second pass on the carder. She takes three pieces of roving and combines them into one larger piece of roving. This helps the yarn spin more uniformly and results in a fabric, when made from the yarn, wear more uniformly.

Then, the roving is spun into yarn.

Becky has a small showroom where she sells her finished yarn. She also sells her yarn online.

In the next few days, we will receive a shipment of Becky's beautiful yarn. We are so excited! I hope you will stop by the shop to squish this yarn for yourself! Her work and her mill are absolutely amazing and inspiring and we are so grateful to her for showing us around.